Acrylic sheet has good processing performance, common processing methods are as follows:

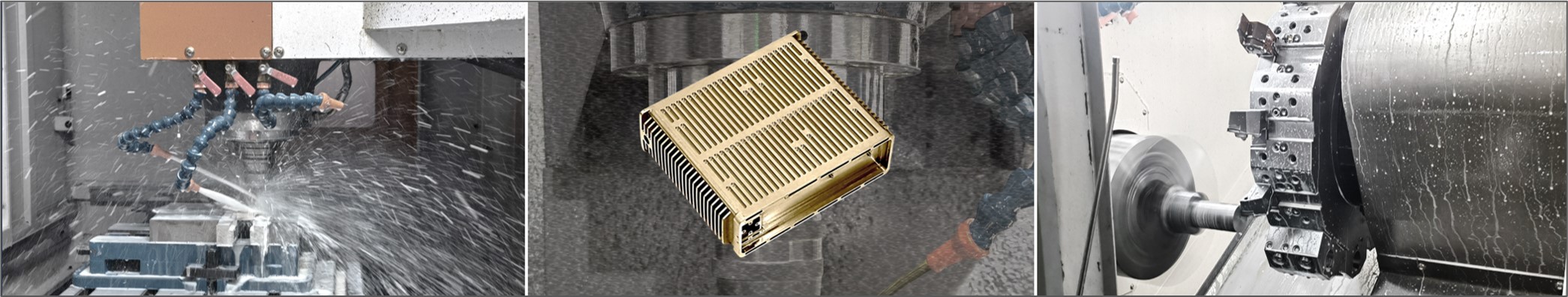

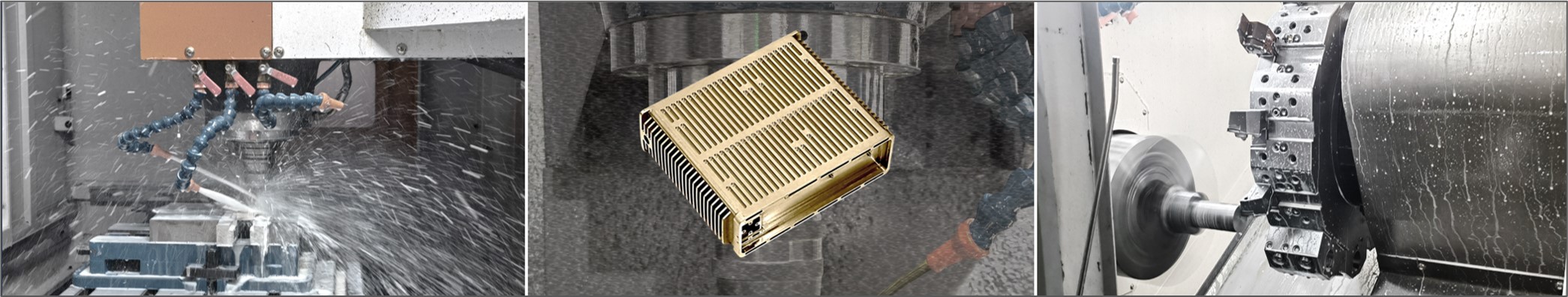

1, cutting: acrylic sheet can be cut using manual or automatic cutting machine. Cutting to ensure that the saw blade sharp, moderate speed to avoid melting or cracks.

2, drilling: acrylic panels can be drilled using a drill. Drilling should choose the right drill bit, moderate speed, to avoid overheating leading to melting or rupture.

3, hot bending: the use of hot air guns, hot bending machine or other heating equipment to heat the acrylic sheet to a certain temperature, then bending. In the heating process to maintain a uniform temperature, to avoid local overheating caused by deformation or bubbles.

4, polishing: you can use the polishing machine, grinding wheel, cotton wheel and other tools to polish the surface of the acrylic plate to improve the surface finish. Polishing should pay attention to moderate speed, avoid overheating.

5, engraving: acrylic plate can be engraved by engraving machine or laser engraving machine to achieve a variety of patterns and text. Carving should choose the appropriate tool and parameters to avoid damaging the material.

6, bonding: you can use special acrylic adhesive to bond acrylic panels. When bonding to ensure that the contact surface is clean and flat to improve bonding strength.

Processing acrylic sheet need to pay attention to the following points:

1, use the right tools and parameters: according to the processing method to choose the right tools, such as saws, drills, knives, etc., as well as the right parameters, such as speed, temperature, etc..

2, avoid overheating: in the processing process, to avoid overheating resulting in acrylic sheet melting, deformation or bubbles.

4, prevent rupture: pay attention to the intensity of the operation during processing to avoid cracks or rupture.

5, keep clean: in the processing process to keep the working environment clean, to avoid dust and impurities affect the processing quality.

6, control processing errors: in the cutting, drilling, hot bending and other processes to control the processing error to ensure the accuracy of the product size.

7, pay attention to safety: pay attention to safety protection in the operation process, such as wearing protective glasses, gloves, etc., follow the operating procedures to prevent accidental injury.

8, control the contact time: when bonding acrylic panels, you need to control the contact time to prevent the glue from penetrating into the interior of the acrylic panels, affecting the product aesthetics and structural strength.

9, good fixed: in the process, to ensure that the acrylic plate is fixed and stable, to prevent shifting or shaking lead to processing errors.

10, avoid stress: in the processing to try to avoid internal stress, because the internal stress of the acrylic sheet may lead to cracks or rupture.

11, to prevent scratches: in the processing to avoid scratches, such as the use of soft cloth or soft pads to protect the acrylic surface to avoid scratching.

In short, when processing acrylic sheet, you should choose the appropriate processing methods and tools, pay attention to the operating specifications and safety, control the processing error, in order to ensure the processing quality and product performance.