The precautions of POM processing process mainly include the following aspects:

Selection of materials: In order to ensure the mechanical and chemical properties of the product, you should usually choose better materials for processing, which can reduce the risk of substandard products due to material factors.

Precautions during processing:

POM can be processed without pre-drying, but it should be preheated to about 80°C before processing, which helps to maintain the dimensional stability of the product and good processing results.

The processing temperature range of POM is narrow, generally below 220°C. Therefore, it should be processed to ensure that the temperature is not too high to avoid decomposition of the material and generation of harmful gases.

The screw speed of POM should not be too high to ensure product quality.

In order to reduce pressure drop, the holding pressure should be near the injection pressure to minimize product defects caused by pressure drop.

POM products have a large shrinkage rate and are prone to shrinkage and deformation, so sufficient space needs to be reserved during manufacturing.

Requirements of the processing environment:

The mold and material temperatures during POM processing should be controlled at a low level to reduce thermal deformation of the material.

Higher temperatures when the product is removed from the mold require safety precautions to prevent burns.

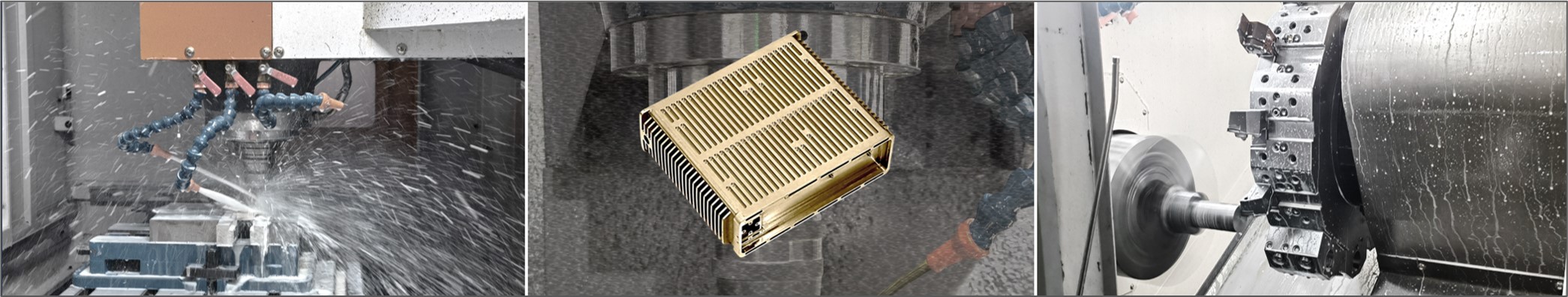

Precision machining considerations:

POM is a high mechanical strength material suitable for precision machining, but its surface may require a secondary sanding treatment, especially in the detail section.

For precision products, it is recommended to use the method of controlling the mold temperature to ensure the accuracy and quality of the product.

Other Precautions:

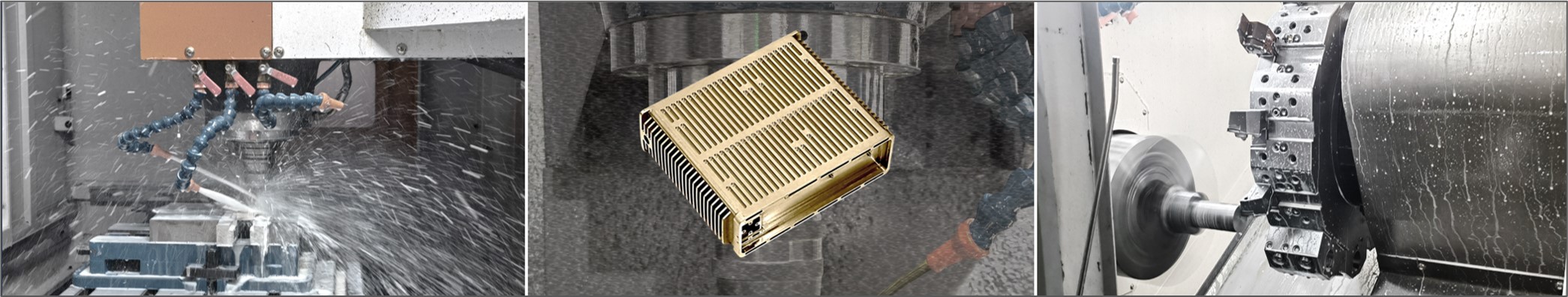

In milling processing, the temperature of the tool should be ensured to be appropriate, and attention should be paid to the reasonable temperature of the cutting fluid, as well as the selection of cutting parameters, in order to achieve the best processing effect.

In turning machining, carbide or PCD tools should be selected and subject to strict quality inspection and resharpening.

In drilling processing, appropriate methods should be adopted, such as gradually expanding the diameter of the drill bit to reduce the collapse and deformation of the hole wall

Translated with DeepL.com (free version)