Electrical Discharge Machining (EDM) is an amazing technology that allows for the creation of complex shapes from a variety of conductive materials and produces tight tolerance parts with excellent finishes.EDM is a subtractive electrothermal manufacturing method that utilizes electrical power to erode the surface of a part.

EDM Basics

In general, EDM can be used to produce any electrically conductive part, even those made from hardened workpieces and other materials that are typically difficult to machine. The process does not create a heat-affected zone, so thin walls and complex geometries can be produced without warping or distortion.

In order for EDM to work, both the workpiece and the electrode material must be electrically conductive, as the process is actually "electrical". The process utilizes the charge between the workpiece and the electrode to create an EDM corrosion that erodes the material on the workpiece. There are two common types of EDM mechanisms: conventional (also known as open mold or sinker) and wire-cut EDM.

Wire Cut EDM vs. Sinker EDM Machines

In EDM wire cutting, a wire acts as an electrode, which creates an electrical charge between the conductive part and the wire. This charge cuts the workpiece like a band saw, but the wire does not touch the part.

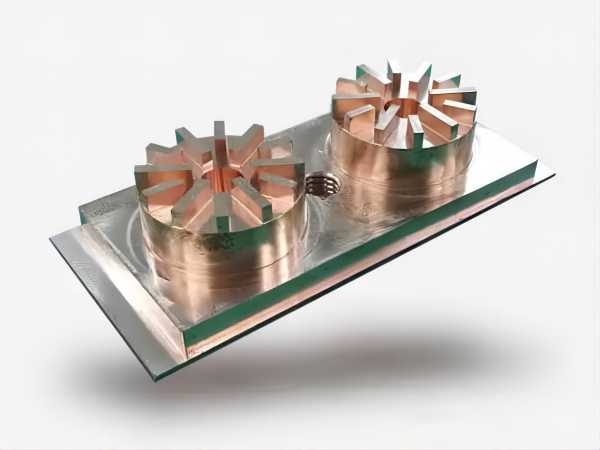

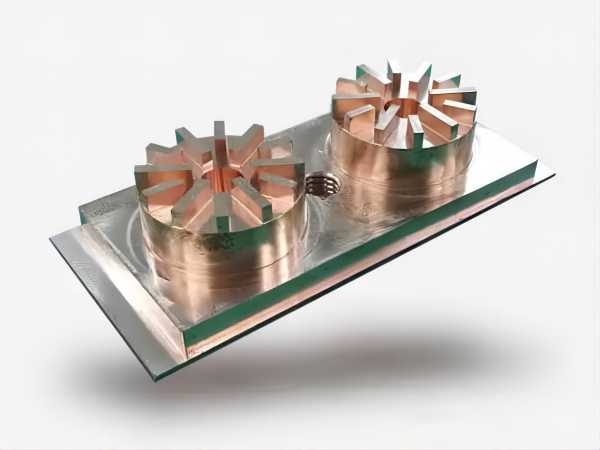

In sinker EDM, the pre-machined conductive electrode has the opposite shape of the part it is to be manufactured. The EDM machine feeds the electrode downward into the workpiece that is submerged in a dielectric fluid. From there, the workpiece is eroded by the charge. The process removes material and creates a cavity in the workpiece that is the same shape but slightly larger than the electrode.

Sinker EDM machines use consumable parts (or wear parts) including pneumatic valves, contact sleeves, nozzles, bearings and electrodes that must be replaced periodically as they wear. Replacing electrodes requires CNC machining of the conductive workpiece to create the necessary dimensions. Copper alloys are commonly used for EDM electrodes, in part because they are easy to machine.

Sinker Electrode Material Selection

The manufacture of sinker EDM electrodes plays a major role in the quality of the finished product, and choosing the right material is critical if you want a high-quality electrode. Graphite, tungsten carbide and copper alloys are commonly used as electrodes.

Copper alloys are commonly used for electrodes because they have higher durability and conductivity compared to graphite. They also have better machinability compared to tungsten carbide and relatively low tool wear considering their material removal rate.

Different copper alloys can be considered for EDM electrode materials, including copper tungsten and brass. In general, these electrodes produce a mirror-like surface finish and are suitable for small cavities. Copper-tungsten sintered electrodes are heat resistant, have high electrical and thermal conductivity, and have relatively low wear rates relative to the rate of material removal. Brass, a mixture of copper and zinc, is an excellent electrode material for less precise work because it is a softer material.

CNC Machining of Sinker EDM Electrodes

CNC machining is the best method for manufacturing copper EDM electrodes because it creates precise and intricate details at a relatively fast rate and at a low cost. CNC machining is also versatile enough to produce complex geometries as well as simple features such as flat surfaces. Additionally, when a CNC machining electrode wears out beyond its useful size, an identical electrode can be easily made to replace it.

Obtaining CNC machining electrodes is a relatively simple 5-step process:

Design: First, you must design the electrode. The electrode is designed as a negative for the shape you are trying to machine using EDM. Ensuring that the part drawing and solid model are complete and in the correct tolerances is key. Accurate GD&T will ensure consistency of the 3D part model and smooth handover to the CNC machining supplier.

Ordering: After submitting a quote request, your CNC machining supplier will review their capabilities to ensure they have the equipment to machine the electrodes to the specified requirements. You will then be provided with pricing and lead time information - please note that due to the small size of the part, the unit cost of electrode machining may be higher than usual.

Machining: Once you have agreed on pricing and placed your order, your supplier will perform the initial setup, including designing fixtures as needed and programming the CNC machine to meet your part requirements. The electrodes are then machined according to the drawing requirements.

Post-processing: CNC-machined EDM electrodes typically require minimal post-processing. Sandblasting or cleaning of sharp corners may be required to ensure the electrode is easy to handle.

INSPECTION AND DELIVERY: The CNC machined electrodes will be inspected to ensure that they conform to the drawings, the specifications of the purchase order, and any requirements presented. Inspection can be done using micrometers and gauges or a coordinate measuring machine (CMM) to ensure quality.

As you can see, sourcing copper EDM electrodes for any design is relatively simple with the help of CNC technology. Copper alloy electrodes are highly machinable and conductive, making them an excellent choice for your next sinker EDM project.