What is non-standard parts machining?

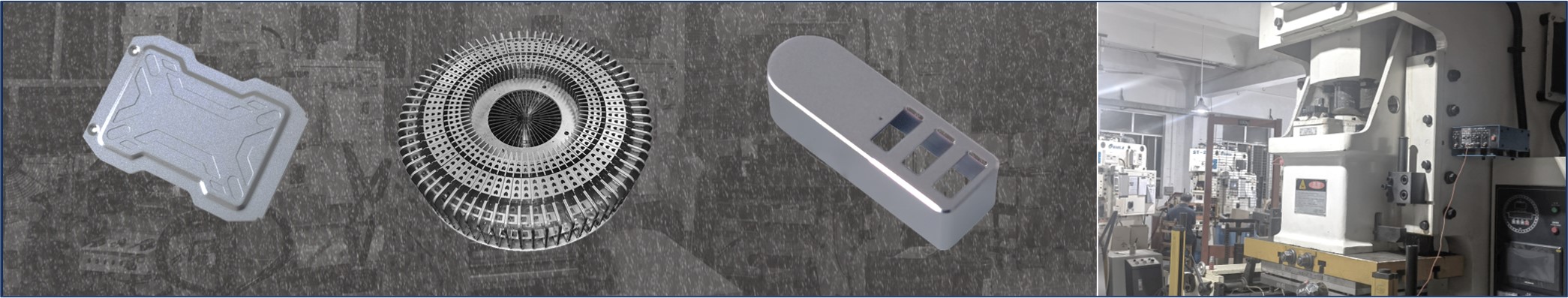

Non-standard parts machining is the use of processing machinery and equipment to grind or cut off the excess part of those parts, so that the whole non-standard parts look more beautiful, but also allows us to better use.

Standard parts are the general rule of general-purpose machinery that can be used in accordance with the manufacturing scale specified by the state. On the contrary, non-standard parts machining must be carried out in accordance with specific regulations, which machined parts are only owned by the manufacturers themselves, non-standard parts machining is the biggest advantage of customized processing. Non-standard parts machining is a manufacturing process that involves a group of non-standard parts forming operations performed by removing material (either through chip removal or through abrasion) by means of machining machinery and equipment such as CNC lathes.

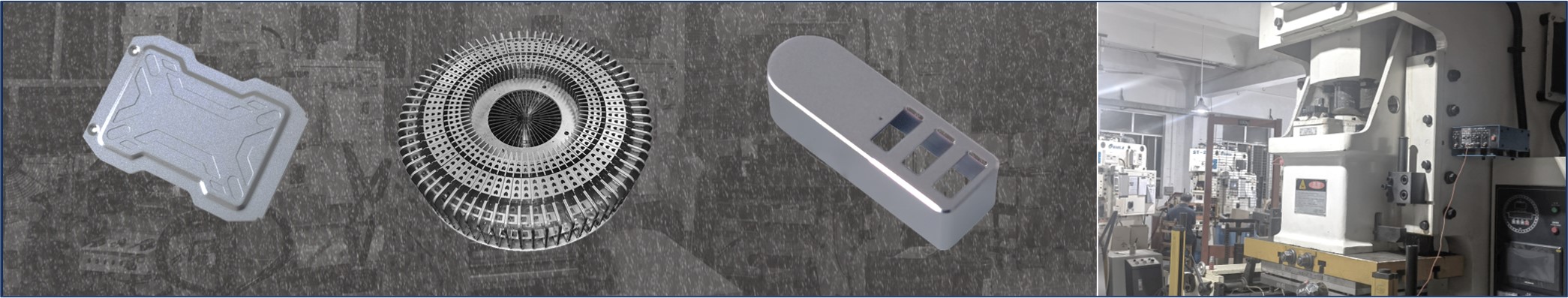

The machining of non-standard parts requires the use of specialized industrial machinery specifically designed for non-standard parts machining to perform the required machining and modifications to the shape of the non-standard part and the dimensions of the non-standard part. The method of machining of non-standard parts will take two different methods of machining depending on the type and nature of the object.

All metal non-standard parts machining (except castings) undergo at least one metal forming operation at some point in their manufacturing process, and often require several different operations. The theory of metal forming can help determine how to use machine tools and equipment in a more efficient manner, as well as increase productivity.